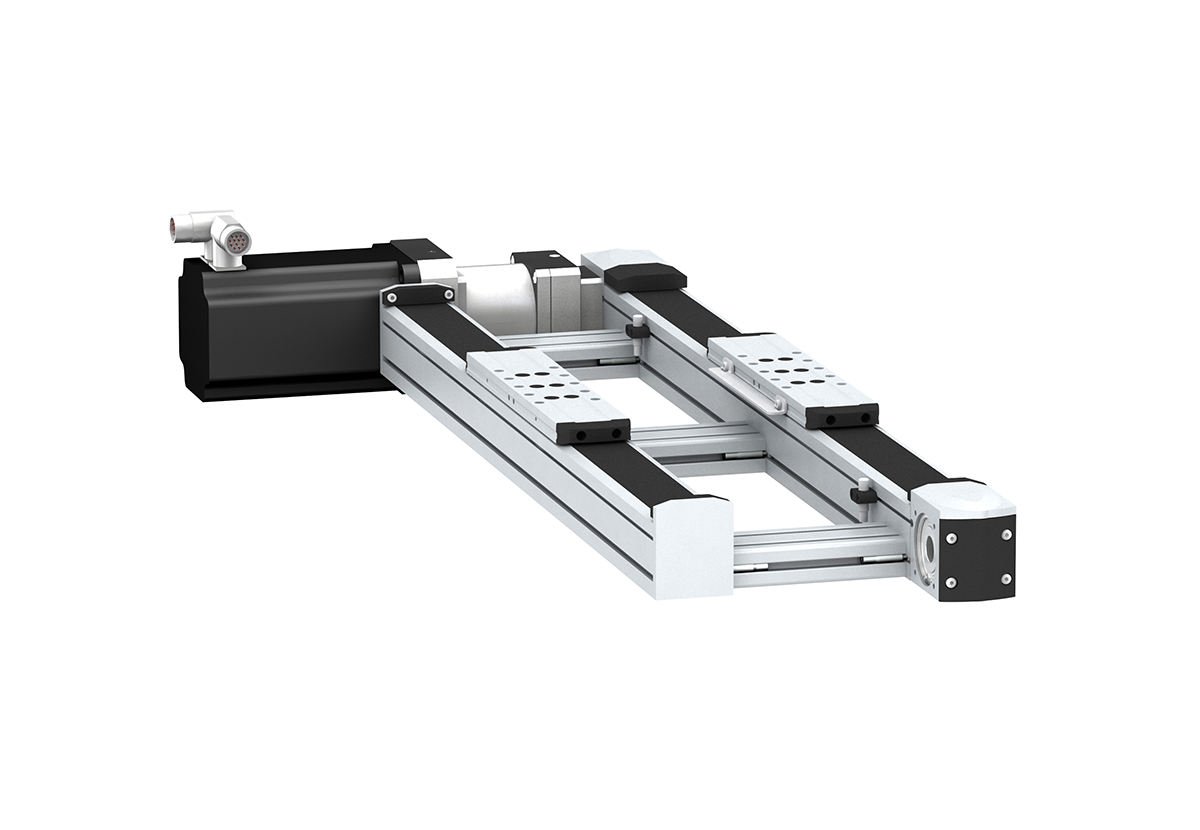

Benefits

With T-slots on 3 sides for simple integration into existing structures

- Carriage with drill holes for easier load mounting

- Grease nipples accessible on each side of the carriages to simplify routine maintenance

- Quick-coupling system for simple motor assembly

- Strokes can be set to the nearest millimetre

- Option to position sensors anywhere along the profile thanks to the T-slots

Features

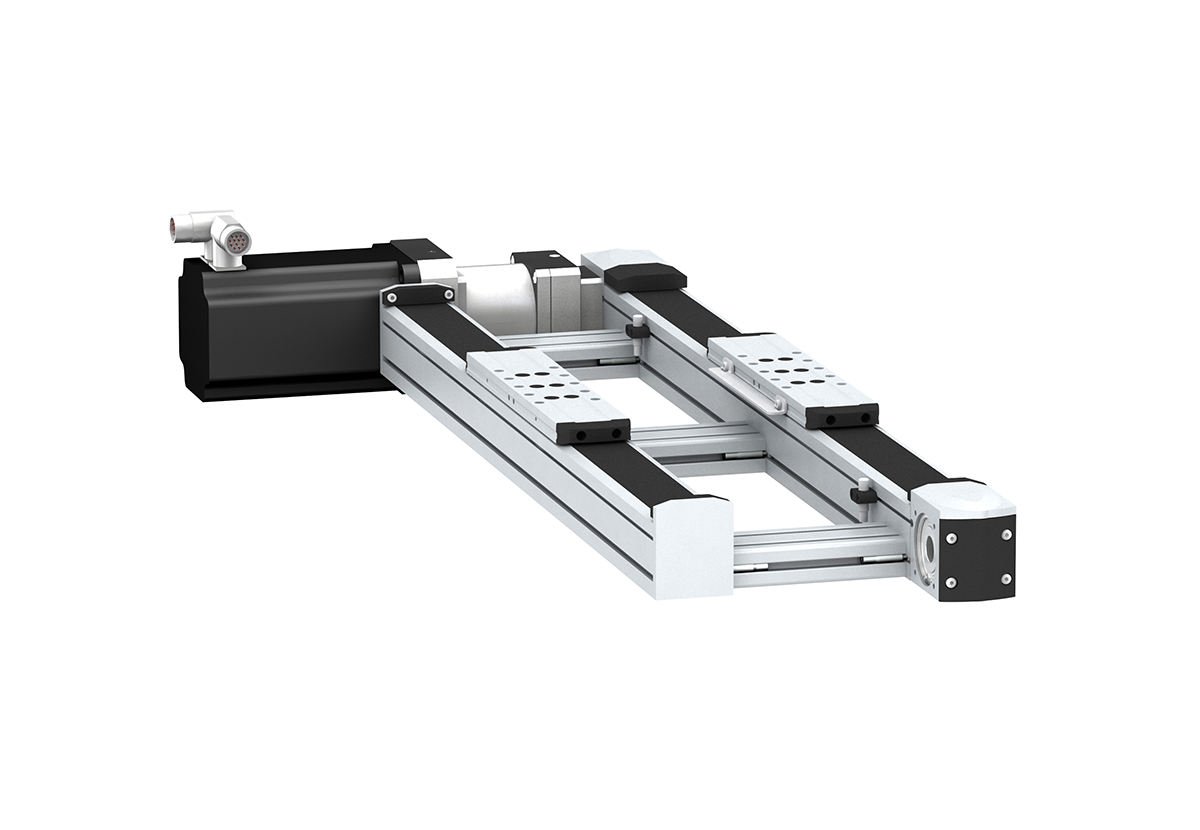

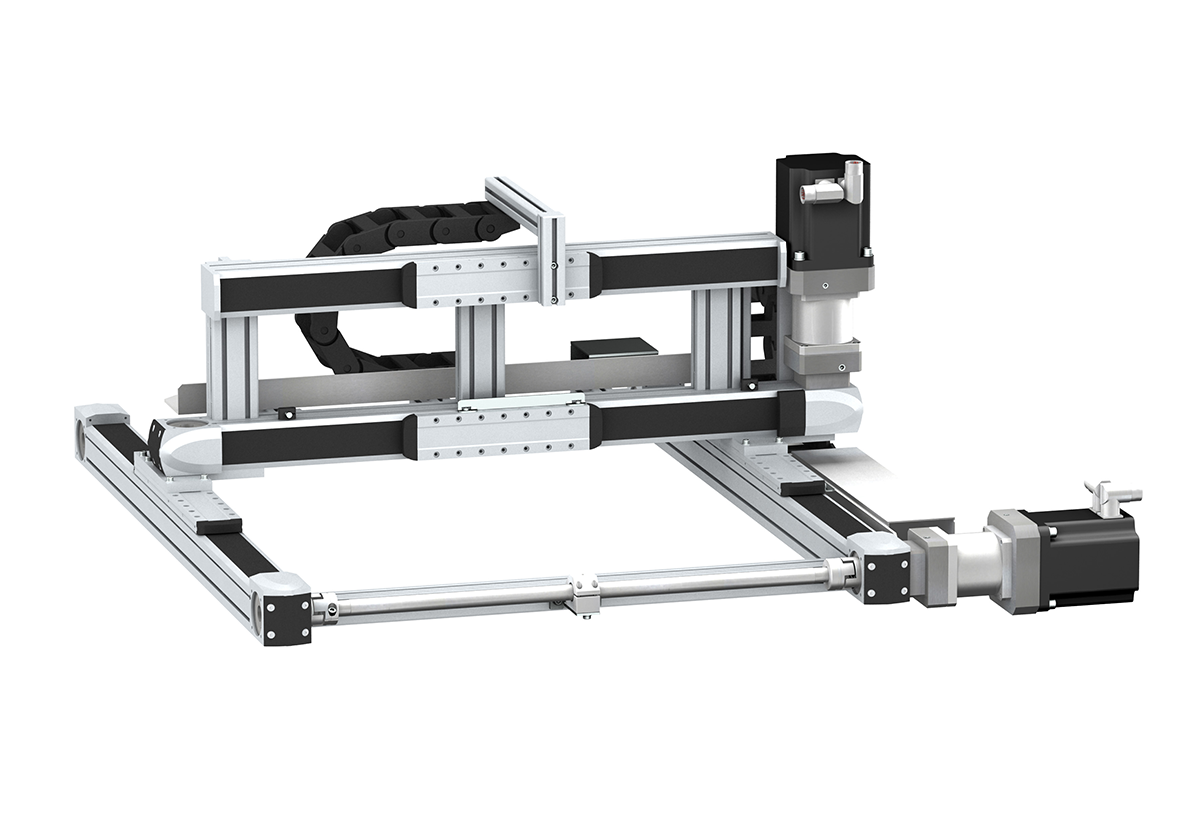

Lexium MAX H and Lexium MAX S double portal axes (one direction)

Applications requiring precise and dynamic load handling over long distances such as material handling, optics and pick and place.

- Lexium MAX H are one dimensional portal axes: consists of a driven toothed belt axis and a non driven support axis.

- Lexium MAX S are one dimensional portal axes: consists of two toothed belt driven axes, synchronized over a synchronous shaft.

- Highly dynamic even with heavy loads.

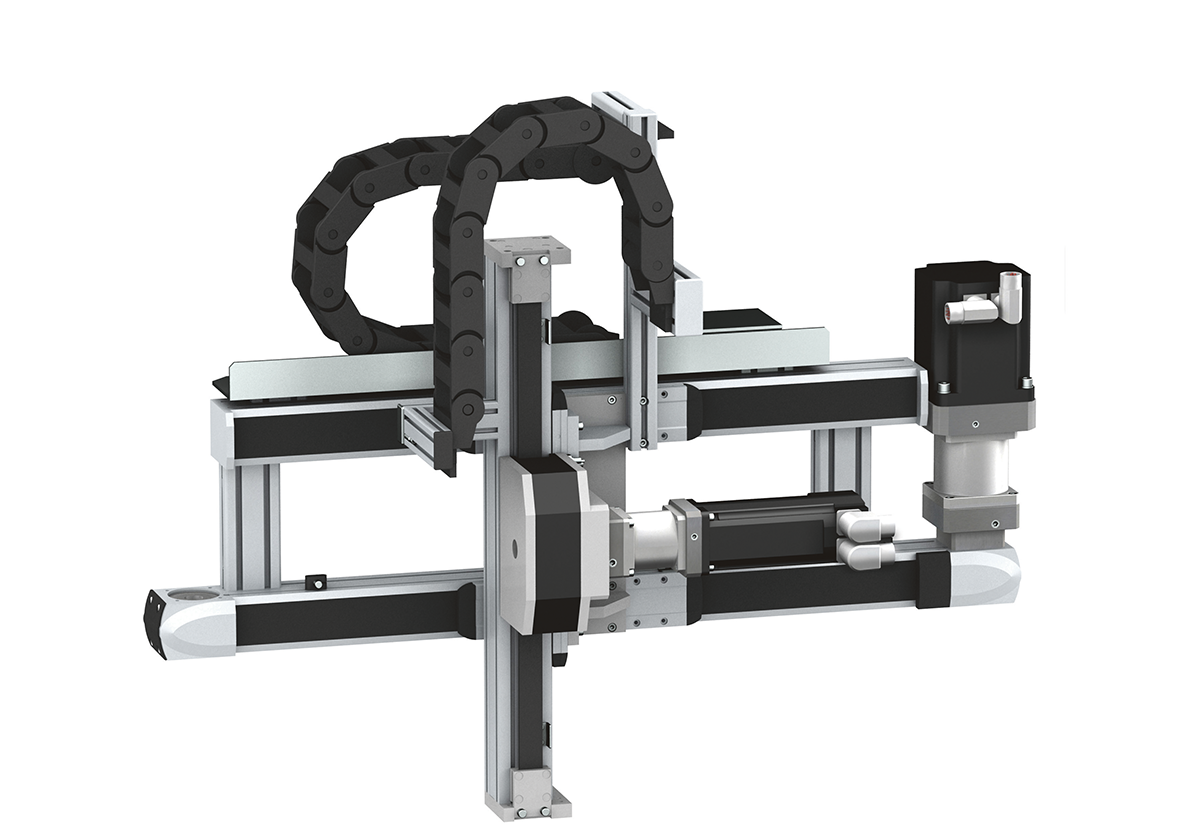

Lexium MAX P linear positioner (two directions)

Applications requiring dynamic handling of parts from or to conveyor belts, loading and unloading of containers, sorting and arranging of parts from containers or into containers.

- Lexium MAX P is an two dimensional portal robots: Lexium MAX H providing motion in direction X, Lexium CAS 4 or a Lexium CAS 3 Cantilever axis providing motion in direction Z

- The linear positioner MAXP is used above or below the working area for moving loads with long X and middle Z movements.

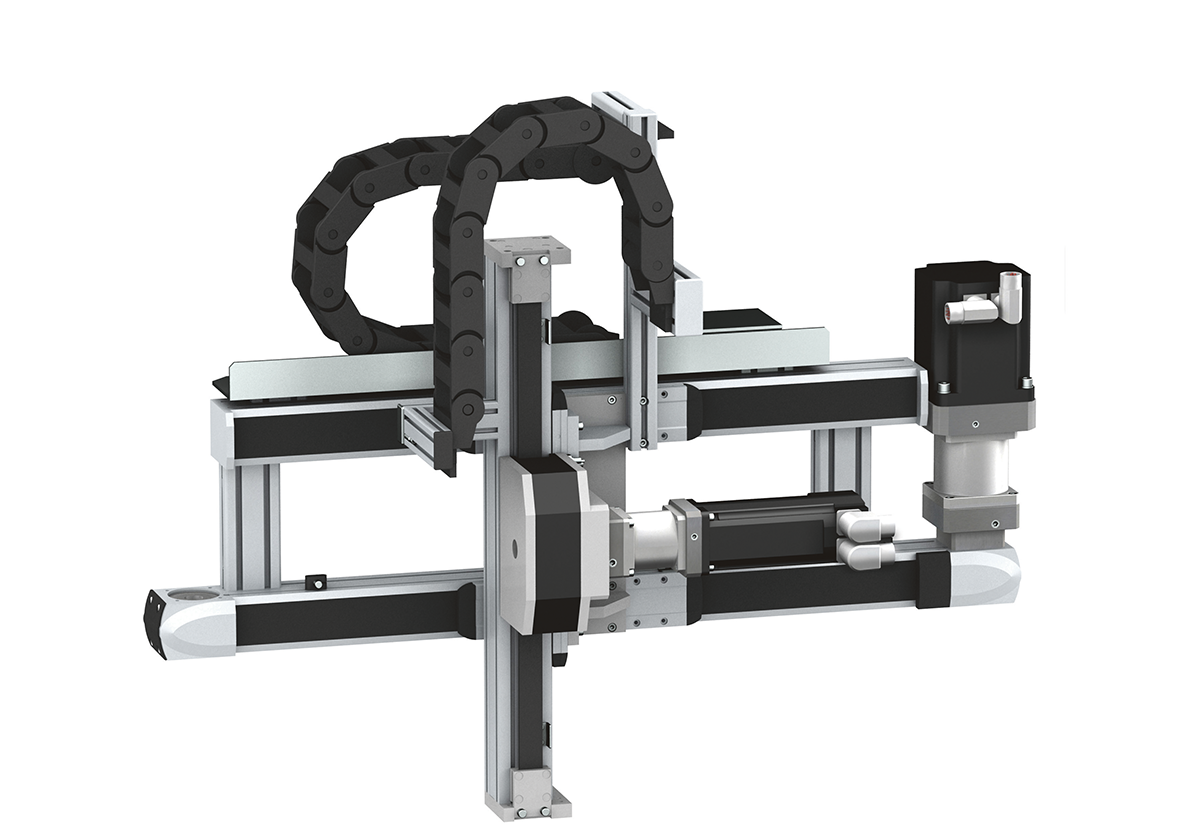

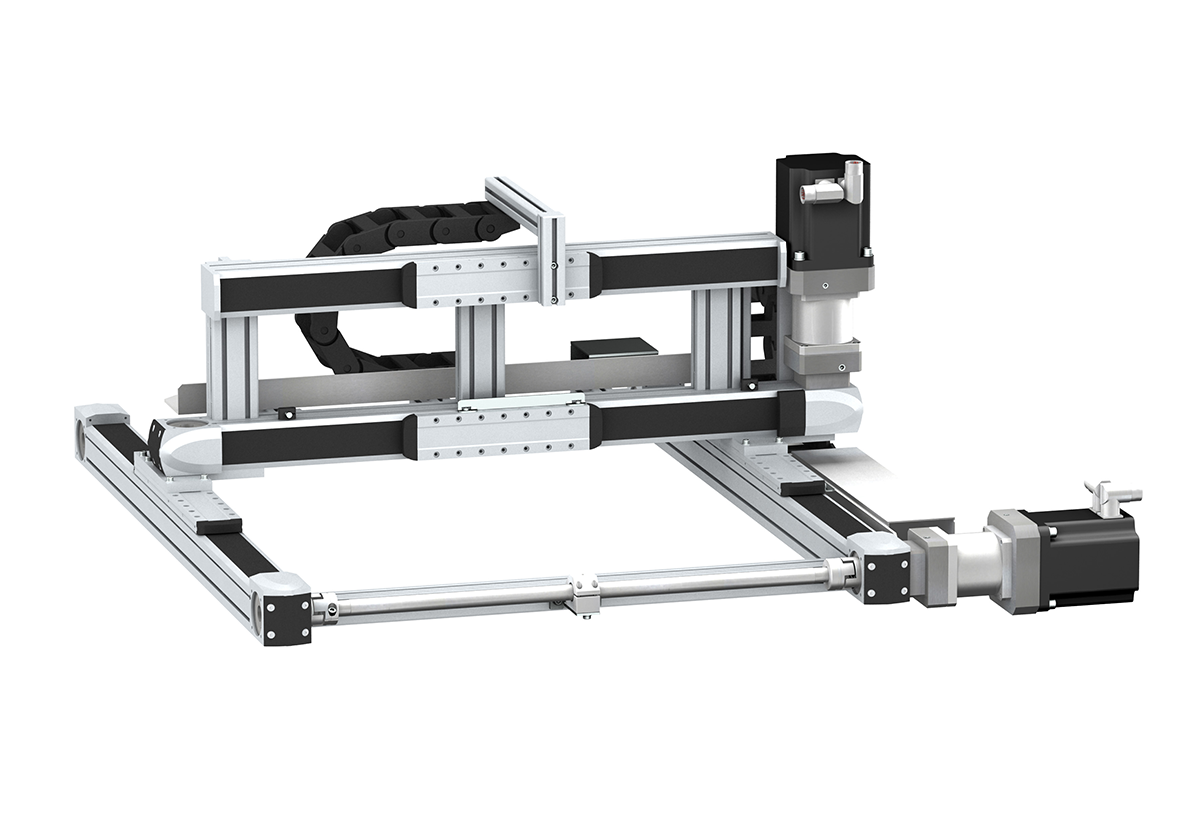

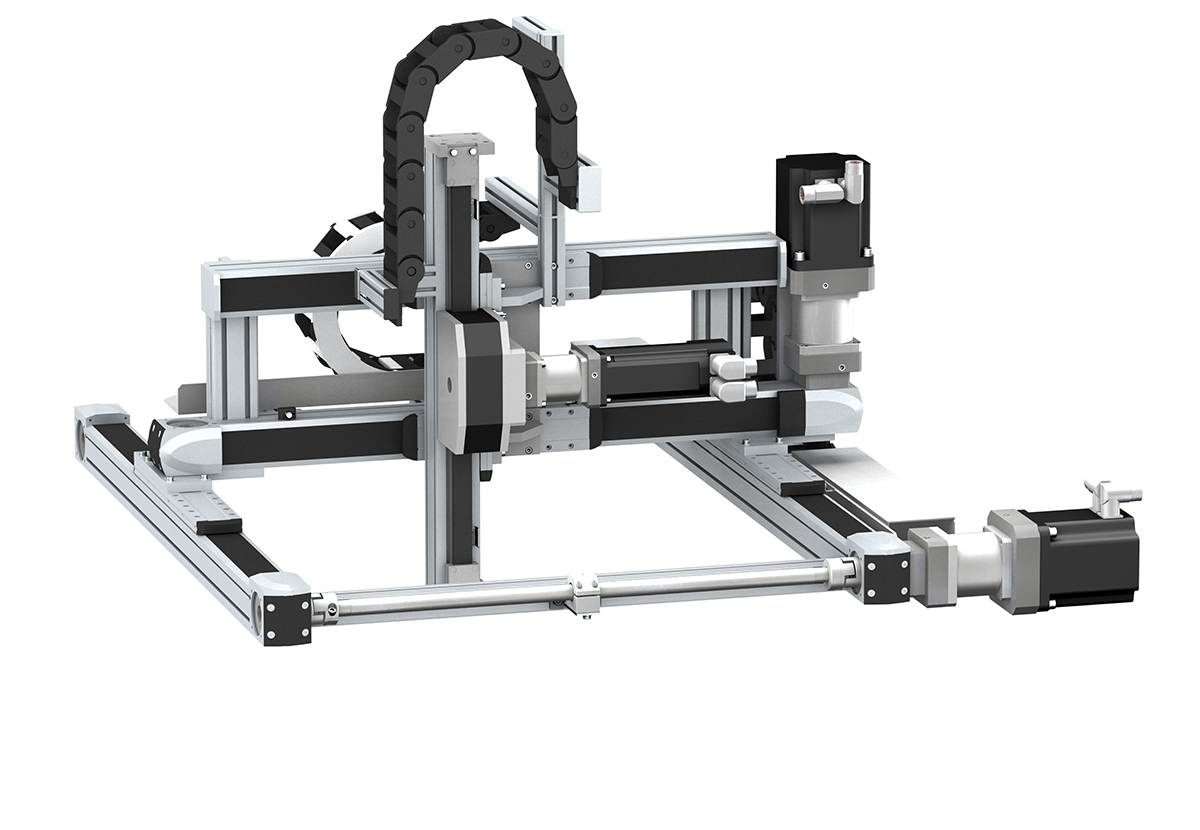

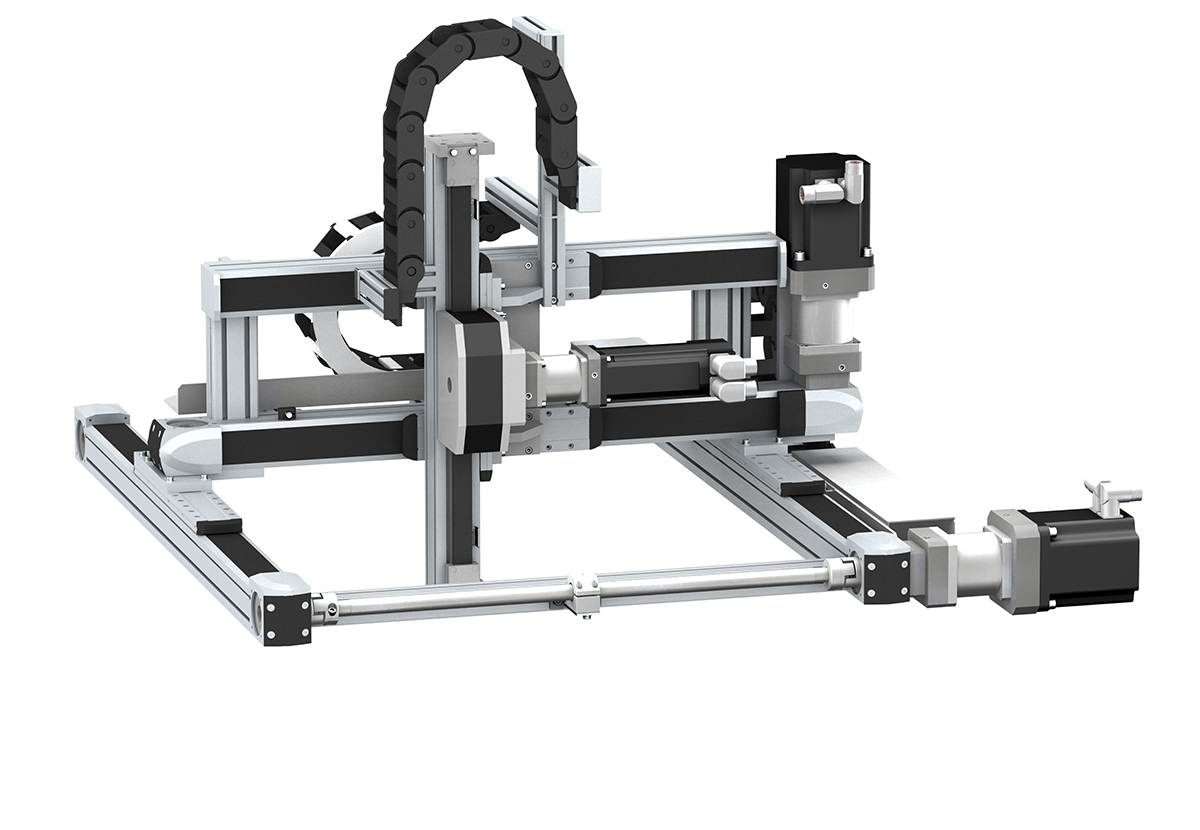

Lexium MAX R.2 and Lexium MAX R.3 portal robots (two or three directions)

Lexium MAX R.2 is a two dimensional portal robot:

- Lexium MAX S providing motion in direction X

- Lexium MAX H or a Lexium PAS B portal axis providing motion in direction Y

Lexium MAX R.3 is a three dimensional portal robots:

- Lexium MAX S providing motion in direction X

- Lexium MAX H providing motion in direction Y

- Lexium CAS 4 or a Lexium CAS 3 Cantilever axis providing motion in direction Z

All types are complete systems, equipped with mounted cable drag chain, motors and gears! This is saving time when raising the machine